电商详情

- 产品介绍

The Shanghai Mingzhu Phase II subway vehicle is the first urban rail project order obtained by CRRC Zhongzhu Zhuji Co., Ltd. The project has a total of 28 rows and 168 vehicles; the vehicle is powered by 1500V DC contact network, and the 4th and 2nd tow 6 sections are grouped. The train design of the power car has a top speed of 100 kilometers per hour and a maximum speed of 80 kilometers per hour. The car body should adopt large-scale extruded hollow aluminum profiles, modular and lightweight structure, and the bottom frame has no central beam overall bearing structure; the bogie is bolster-free structure, low-alloy steel plate welded frame, and the second-series suspension form; Designed according to European and related international standards, CRRC plant production. The single-car has a passenger capacity of 318 passengers and has a total passenger capacity of 1,860 passengers. It is currently the largest passenger car in the world's metro vehicle family. Up to now, CRRC Zhuji has provided a total of 1,880 subway vehicles to Shanghai, with a total length of more than 42 kilometers. All vehicles can have more than 700,000 passengers at a time.

Development process

Signing a purchase contract on March 25, 2002

Project launch in June 2002

Approved by the electric drive system in January 2003

Approved by the overall technical program in August 2003

First line on December 18, 2004

Delivered to the Shanghai project site in February 2005 to deliver the owner

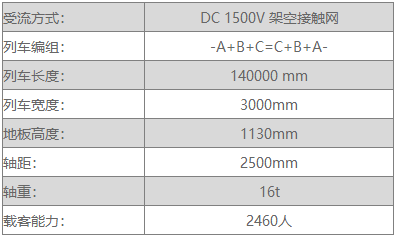

Key technical parameters

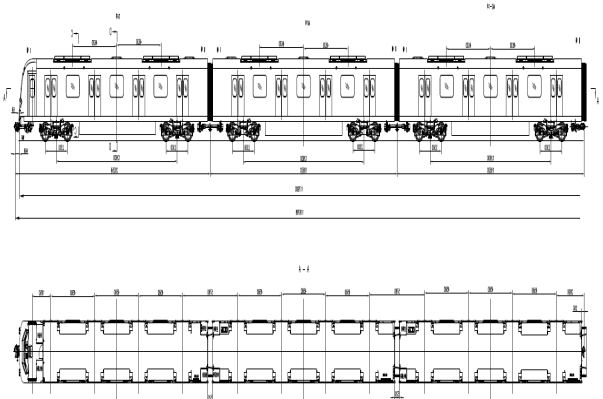

The train formation map is as follows

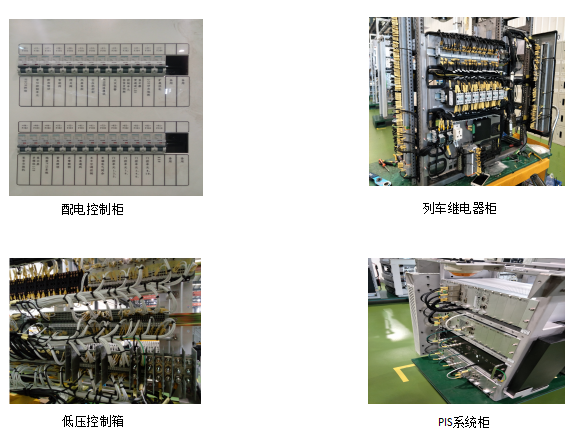

Our product advantages:

Operating temperature range -40 to +70 °C

According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

Anti-vibration and shock resistance

Meets the vibration and shock resistance requirements of EN50155, IEC61373;

Cage spring clamping technology ensures that the product is reliably connected under vibration conditions.

Low smoke, halogen free, flame retardant

Wide voltage range:

Control voltage range from 0.7 to 1.25Us, integrated surge suppressor

According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

湘ICP备19024974号-1