电商详情

- 产品介绍

The entire project of Kunming Metro Line 1 designed and developed by CRRC is equipped with 40 columns and 6 sections (4 sections of trains and 2 sections of trailers). It is completely tailored according to the local geographical environment and climate of Kunming. The train has a speed of 100 kilometers per hour and a maximum passenger capacity of 1870. The whole vehicle adopts high-strength all-welded aluminum alloy body technology. The traction system, network control system and drive system adopt domestically produced equipment. The interior lighting uses LED energy-saving technology. The train is The first high-altitude subway in China. The front part of the train adopts a buffer, a crusher, an anti-climbing device, and a deformation zone. The four-stage energy absorption collision avoidance safety design is called the five-star safety of the metro vehicle in China. At present, the CRRC car plant in Kunming has successively received train orders for several subway projects such as Line 3, Line 6, Line 4 and Line 5.

Development process

Signed a project contract in December 2011

Project launch in March 2012

In June 2012, passed the electric drive system program review

Adopted the overall technical program review in October 2012

The first train was dropped in January 2013

The trial operation was officially opened on November 5, 2013.

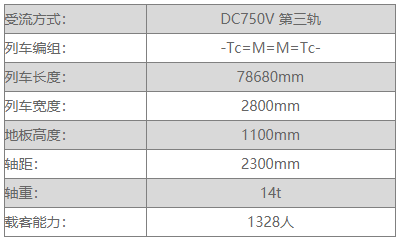

Key technical parameters

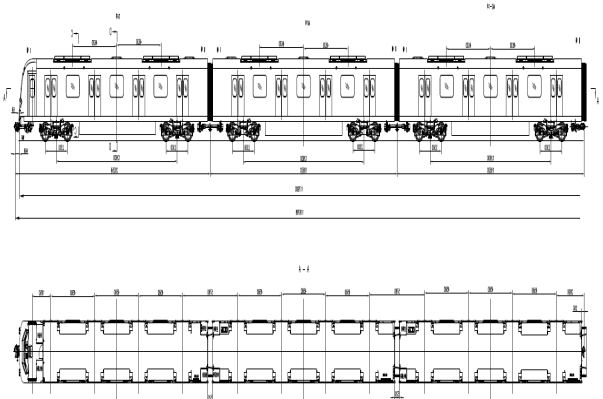

The train formation map is as follows

Our product advantages:

Operating temperature range -40 to +70 °C

According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

Anti-vibration and shock resistance

Meets the vibration and shock resistance requirements of EN50155, IEC61373;

Cage spring clamping technology ensures that the product is reliably connected under vibration conditions.

Low smoke, halogen free, flame retardant

Meets EN45545 (HL1 ~ HL3) fire protection standards

Wide voltage range:

Control voltage range from 0.7 to 1.25Us, integrated surge suppressor

According to the standard: IEC60571, IEC60077 (GB21413), EN50155, etc.

湘ICP备19024974号-1